The high tunnel raising

Earlier this week we completed a project I’ve been waiting on since we first knew we were buying this farm… installing our high tunnel!

A high tunnel is a structure with hoops covered by plastic that is typically used by farmers to extend the growing season and sometimes act as a greenhouse in the spring for baby plants. Some people use the terms high tunnel and greenhouse interchangeably, but, to me at least, a greenhouse is a more solid structure with “real” walls, not plastic.

Luckily, I was able to secure a Natural Resources Conservation Service (NRCS) grant for this project, which left us with only about $4,500 to pay out of pocket. Unfortunately, the wheels of these government programs turn pretty slow, so we were unable to get the structure until this year, when ideally it would have been put up last year so I could have used it this spring. Not having the structure led to some difficulties with storing seedlings, as I wrote about in a previous post. I had to keep the little guys in our garage and a small backyard greenhouse which could only hold a fraction of the plants. Without the proper light and temperatures, some of my transplants dampened off, and I had been forced to slow down my seeding schedule due to space constraints, so I am very excited to have the high tunnel to alleviate these issues next year!

Farmers have a lot of opinions about high tunnels I’ve learned. There are many answers to questions like which way the tunnel should face and how long one takes to install. Some farmers spend days or weeks getting one put up; it usually depends on the weather and how many helping hands you have, as well as your experience with the process.

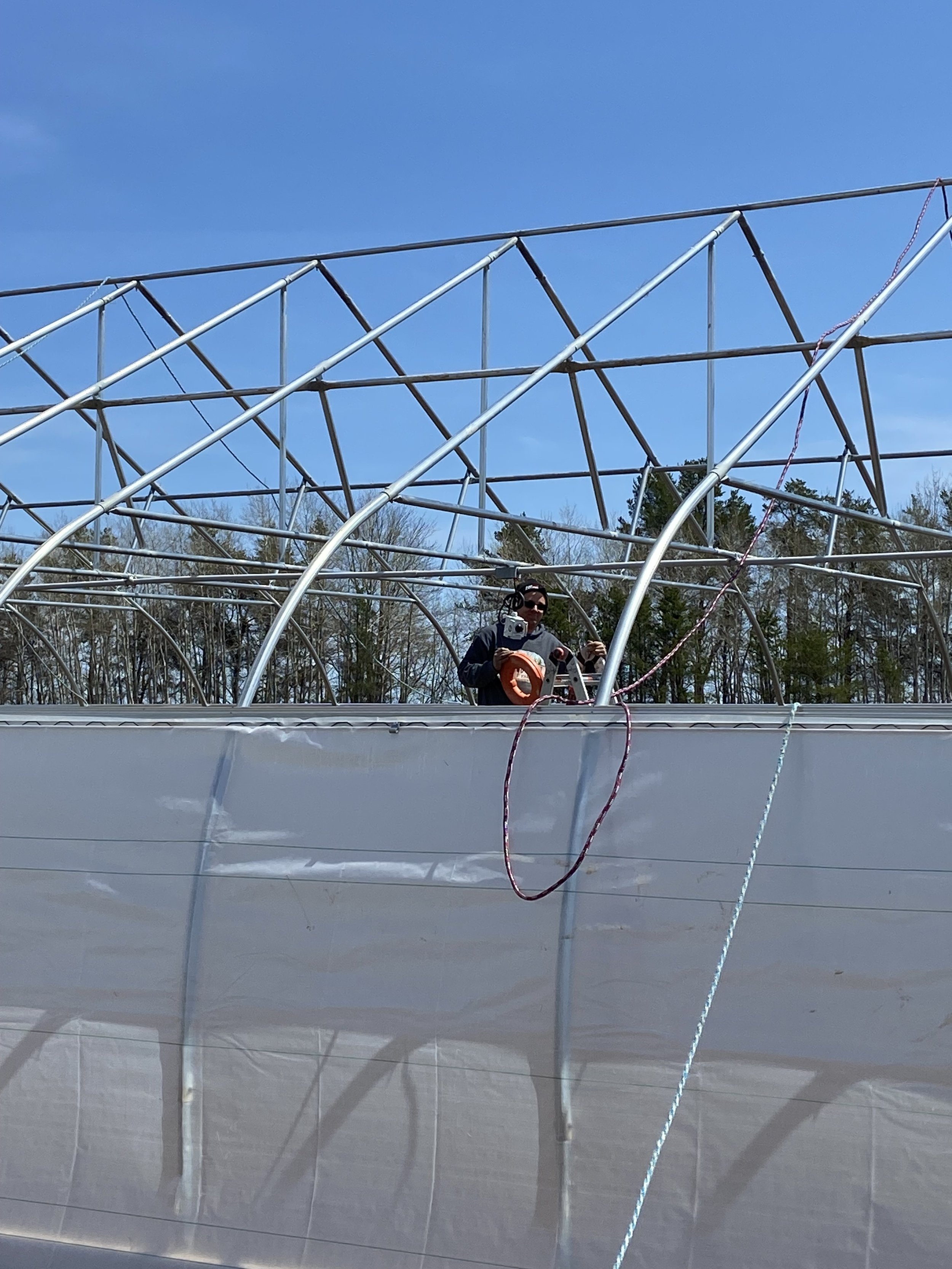

We were lucky that we had a group of 10 able to be here for the build. On top of that, two of the crew were from the company that we bought the high tunnel from, Nifty Hoops. They were the leaders in our “community build,” giving us directions and a lot of help along the way. Without their support, it would have definitely taken multiple days to build and there would have been a lot of unanswered questions and guesswork involved.

It took us about nine hours to complete the high tunnel installation. The guys from Nifty Hoops, Tomm and Blake, came on Tuesday evening to do some preliminary work, like lining up posts and setting things up for the next day. On Wednesday, we started around 7 a.m. and finished up just after 3 p.m. It was a thick, muddy mess in most spots, as it had snowed and rained a couple days before we were set to start. Unfortunately one side of the tunnel is in a pretty wet area of the field, so I will be having to add compost and/or soil to help build up the ground level before planting in there. This is a challenge I think I would’ve had to face regardless of where the structure was placed, as the soil here is clay dominated and the field doesn’t drain well currently. (I’m hoping some soil rehab in the coming years will help that.)

Before this, I had helped install end walls and plastic on high tunnels, but I’d never been involved with a full build. To say it was exhausting is an understatement. I did get more comfortable working while on a ladder, though! It was also amazing to see it all come together and watch others get to witness it, too.

A huge thanks goes to out to everyone who was here to help – Tomm and Blake from Nifty; Tyler and my mom; my uncle Rudy and cousin Izzy; Tim, my farm mentor and previous employer, and his son, Elliot; Matt from Renewing the Countryside who came along to help and learn from Tomm. It was a day I know many of us won’t soon forget!

Here is a sped-up video of us pulling the plastic on the high tunnel! This can be one of the most frustrating parts of an installation, especially with any winds greater than a few mph.